We support "working"

and "working people."

Founded in 1945 by Matsujiro Aoki, Tokai Utensil Manufacturer (currently known as Noritsuisu) started out manufacturing chairs for barber shops.

After that, we began manufacturing office swivel chairs, which became the foundation of our office furniture manufacturing. Currently, in cooperation with many sales companies in Japan, we manufacture a variety of chairs and partitions for the office, as well as for medical and educational markets.

Based on our mission of "Supporting Working People," we aim to respond to the needs of working people through furniture and create products that will be loved for a long time.

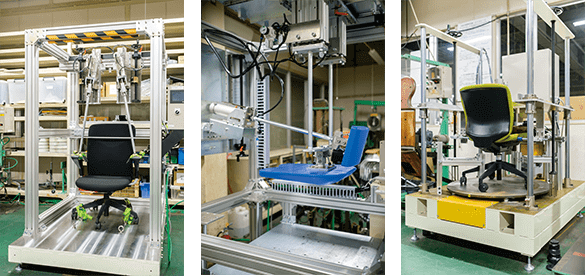

One-stop production system

at our own factory in Japan

All processes from information gathering to design, development, production, and logistics are efficiently carried out in one place.

We specialite in steel processing and tension processing. In addition to the experience and technology we have cultivated since being founded, we have introduced the latest machinery and equipment to meet the various needs of our customers.

Under this one-stop production system, our strength lies in our ability to manufacture high-quality products in small lots and in a wide variety of products, with pride in being made in Japan.

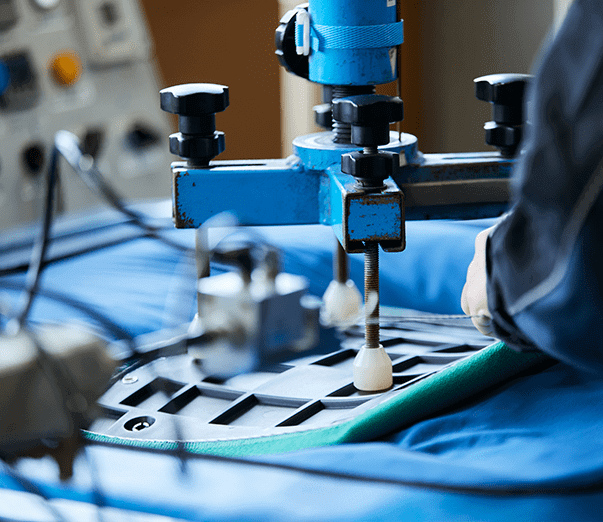

Commitment to quality

We operate a quality management system that complies with international standards (ISO9001),we pursue high quality in our integrated manufacturing process, which is carried out at our own factories in Japan, from planning to design, development, and manufacturing.

We will continue to make further efforts to improve quality and preserve the environment, and actively develop our corporate activities.

Environmental initiatives

We are environmentally friendly by creating products that can be used for a long time, such as by creating products that use environmentally friendly materials,we also design products that can be used for a long time by being detachable and replaceable.

We promote the creation of products that are easy to separate and dispose.

Specific initiatives

- Resource reuse (paper, iron recycling)

-

Reuse of powder coatings

We are equipped with powder coating equipment that does not use organic solvents such as thinners.This is an environment-friendly painting method that reduces the impact on the human body and air pollution, and allows excess paint to be collected and reused. -

Installation of a solar power generation system using the factory roof

Annual power generation: Approximately 380,000 kW/h - Reducing waste through repair support

-

Power saving

Use LED bulbs in offices and factories - Reducing metal scrap

- Manufacturing products using recycled materials

![NORITSUISU CO.,Ltd [EN]](https://www.noritsuisu.co.jp/en/wp-content/themes/noritsuisu_en/img/common/norituisu_logo.png)